| Conveyor Belt-------Resistant Type Conveyor Belt |

|

The Conveystar resistant type conveyor belt systems

include: |

·flame resistant conveyor belt ·heat resistant conveyor belt

·cold resistant conveyor belt ·oil resistant conveyor belt

·acidalkali resistant conveyor belt |

| |

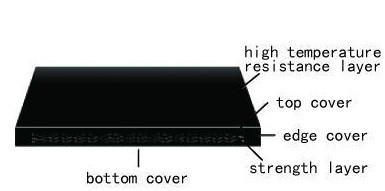

| heat resistant conveyor belt |

|

| Features: |

1.Using cotton polyester canvas as carcass with good heat-resistant rubber material as cover. The general type of this belt could be usually used in the condition of 150℃.

2.Using cotton polyester canvas as carcass with excellent heat-resistant rubber material as cover, the high temperature resistance type of this belt could be usually used in the condition of more than 150℃. |

| Types of Product: |

Four Grades baesd on different heat resistant temperature:

Type 1: used under the temperature≤125℃.

Type 2: used under the temperature≤150℃.

Type 3: used under the temperature≤180℃.

Type 4: used under the temperature of burning. |

| Applications: |

| Widely used in conveying sintering ore, hot coking coal, cement, molten slag, hot casting high temperature materials etc. |

| Technical Requirements: |

| Physical Performance of Cover Rubber |

| Index |

Types |

| type 1 |

type 2 |

type 3 |

type 4 |

| changing scope |

| hardness |

Difference between after agingbefore aging |

20 |

20 |

±20 |

±20 |

| Max. Value after aging |

85 |

85 |

85 |

85 |

| Tensile strength |

Reduction of properties changing rate% ≤ |

25 |

30 |

40 |

-40 |

| Min. Value after aging MPa |

12 |

10 |

5 |

| Elongating at Breaking |

Changing rate of properties%≤ |

50 |

50 |

55 |

-55 |

| Min. Value after aging% |

200 |

200 |

180 |

| Remark: aging test(125℃×168h,150℃×168h,180℃×168h ) | |

| Standard: HG2297-92 Heat Resistance Conveyor Belt |

| Specification |

| Width range |

Plies |

Top cover thickness mm |

Bottom cover Thickness mm |

Length/roll m |

| 200-1500 |

3月12日 |

4.5-9.0 |

1.5-4.5 |

100/200 |

| Remark: Cover thickness, plies of canvaslength per roll can be designed according to the customers’ request | |

| cold resistant conveyor belt |

|

Features: |

| Using cotton, terylene cotton, polyester, nylon canvas as carcass, the belt has advantages of high elasticity cold-resistance of cover rubber which could be widely used under the condition of -45℃. |

| Application: |

| The belt is especially for low temperature conditions. |

| Technical Requirements: |

| Physical Performance Of Cover Rubber |

| Index |

Value |

| Tensile strength Mpa ≥ |

14 |

| Elongation at breaking % ≥ |

350 |

| Abrasion loss mm3 ≤ |

200 |

| Coefficient of Cold resistance |

0.3 |

| when stretched (-45℃) ≥ |

Standard:HG3647-1999 Cold Resistance Conveyor Belt. |

| oil resistant conveyor belt |

|

Features: |

| Using cotton, terylene cotton, polyester nylon canvas as carcass , the belt has excellent oil-resistance property of cover rubber. |

| Application: |

| It’s widely used for conveying oil material. |

| Physical Performance of Cover Rubber |

| Index |

Value |

| Tensile Strength Mpa ≥ |

15 |

| Elongation at breaking % ≥ |

350 |

| Abrasion Loss mm3 ≤ |

200 | |

| Performance of Oil Resistance |

| Number |

In the liquid soaking test Resistance |

Changing rate % ≤ |

| |

GB/T1690 standard oil |

Socking Temperature ℃ |

Socking Time h |

Cubage |

| 1 |

2# oil |

70±2 |

72 |

-4 |

| 2 |

3# oil |

70±2 |

72 |

10 |

| 3 |

4# oil |

100±2 |

72 |

Standard: GB1690-82 Liquid Resistance Testing Method of Vulcanizing Rubber. |

| acidAlkali resistant |

|

Features: |

| Using cotton, terylene cotton (T/C), polyester, nylon canvas as carcass,the belt has good physicalmechanical property with excellent chemical corrosion resistance property of cover rubber. |

| Application: |

| used in chemical fertilizer plant etc that conveys material with acid alkali properties. |

| Physical Performance of Cover Rubber |

| Property |

Value |

| Tensile strength Mpa ≥ |

14 |

| Elongation at breaking % ≥ |

350 |

| Abrasion loss mm3 ≤ |

200 |

| Coefficient of acid and |

0.85 |

| alkali resistance ≥ | |

| flame resistant conveyor belt |

|

Features: |

| Using cotton, terylene cotton, polyester, nylon canvas as carcass, the belt has flame resistant property on cover inter layer rubber. |

| Application: |

| Used in general flame resistant condition. |

| Physical Performance of Cover Rubber |

| Index |

Value |

| Tensile strength Mpa ≥ |

10 |

| Elongation at breaking % ≥ |

350 |

| Flame resistance |

Average flaming times lasts ≤60s on 3 longitudinal total thickness samples without re-burning of each testing result |

| Electrical cinductivity ≤ |

3 × 10 8 Ω |

Standard: GB10822-89 General Flame Resistant Conveyor Belt. |